Advanced Framing – Save on Wood to Save on Energy

Author: Nick Gazo

The instability of wood prices and wood availability in Canada has touched anyone who is building, renovating, or buying a home in the last few years (2021 Lumber Market Outlook, 2021). Project delays and unforeseen mid-project cost hikes have been the hypothetical thorn in the industry’s side, but we should try to see the great opportunity this problem has presented us with.

For decades now, the concept of Advanced Framing has been but a rarely talked about approach to building, and one of its main benefits eases the industry’s pains from the wood shortage. Advanced Framing techniques use less wood by carefully designing the structure to efficiently carry vertical loads down to the foundation. A full course on this topic would be needed to properly cover the necessary technical details, but below is a comparison of Standard Framing to Advanced Framing.

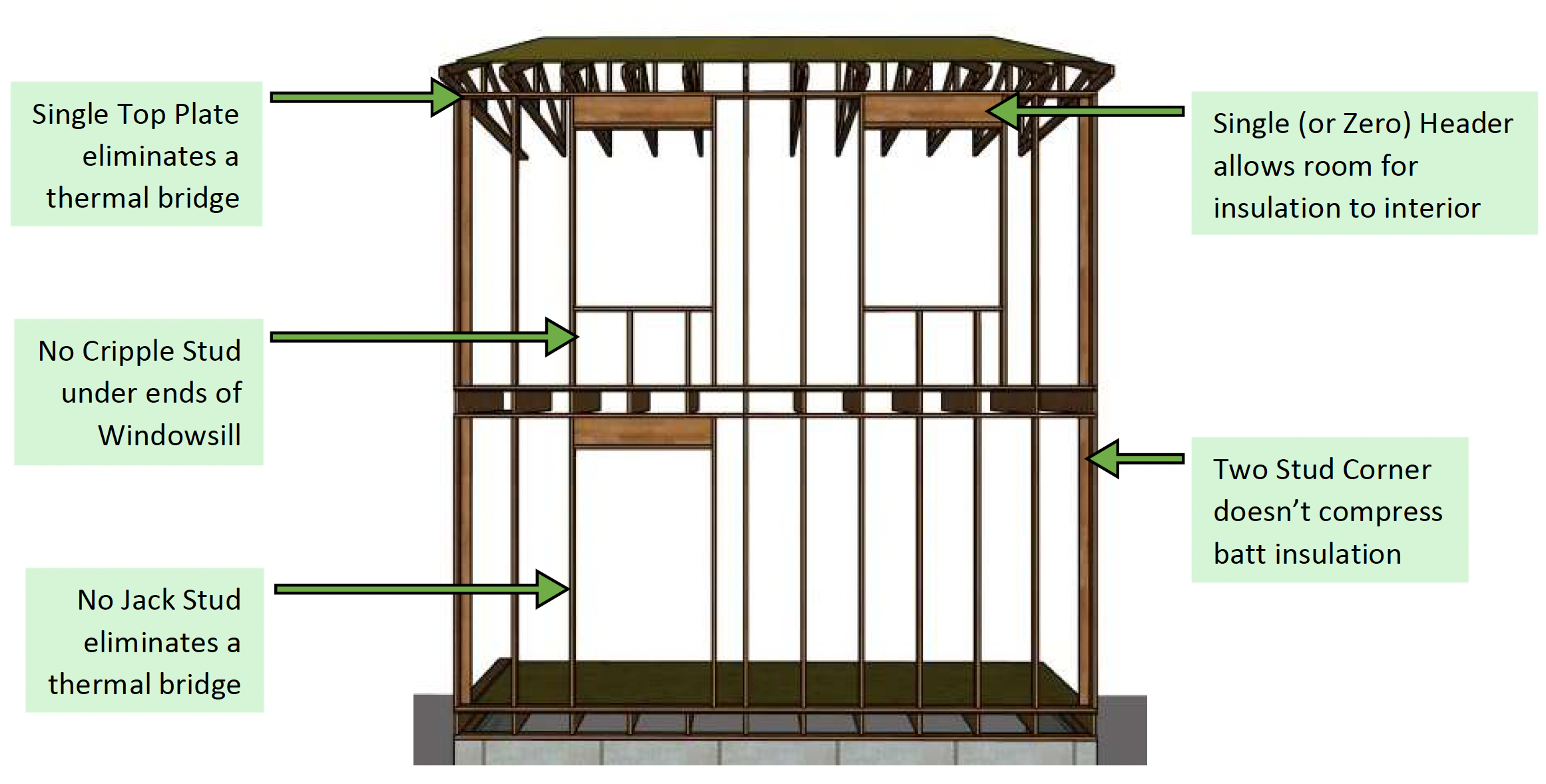

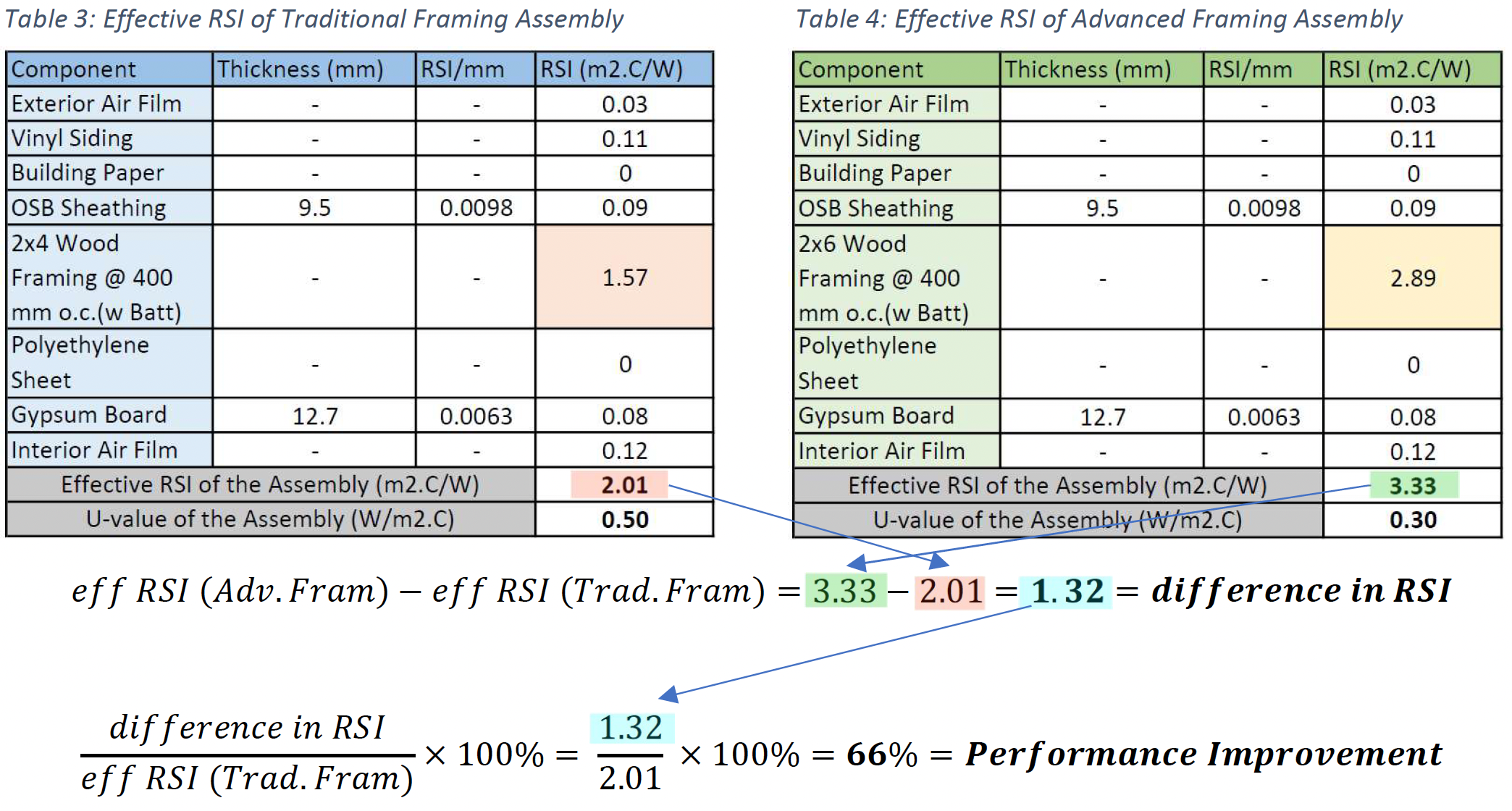

Figure 1: Traditional Framing (left) has far more structural members which are each potential thermal bridges. Advanced Framing (right) has deeper and wider cavities for insulation and has fewer thermal bridges for continuous insulation to thermally guard.

Standard Framing

- 2x4s spaced at 16” o.c.

- Double top plates

- Three stud corners

- Jack studs

- Corner cripple studs

- Double headers

- Framing Factor of 25%

Advanced Framing

- 2x6s spaced at 24” o.c.

- Single top plates

- Two stud corners

- No jack studs

- Fewer cripple studs

- Single headers (sometimes no headers)

- Framing Factor of 15%

The Energy Factor

Reducing the Framing Factor from 25% to 15% means there are 10% less potential thermal bridging locations in an Advanced Framed system for continuous insulation to thermally guard (Lstiburek, 2010). If by increasing stud spacing to 24” o.c. means that 2×6 studs are now needed compared to the 2x4s of Traditionally Framed system, then the deeper cavities can hold 57% more cavity insulation. With framing members fewer and further between, this means that not only does cavity insulation make up 85% of the wall area instead of 75%, but it is also thicker and more effective at reducing heat transfer.

Example of Energy Saved

For the following example we are comparing a Traditional Framed Wall to an Advanced Frame Wall to uncover the value of carefully designing the structural members of the building envelope. All material properties are from NRCan’s Tables for Calculating Effective Thermal Resistance of Opaque Assemblies. (Tables for Calculating Effective Thermal Resistance of Opaque Assemblies, 2016).

Figure 2: Traditional Framed Wall System

Figure 3: Advanced Framed Wall System

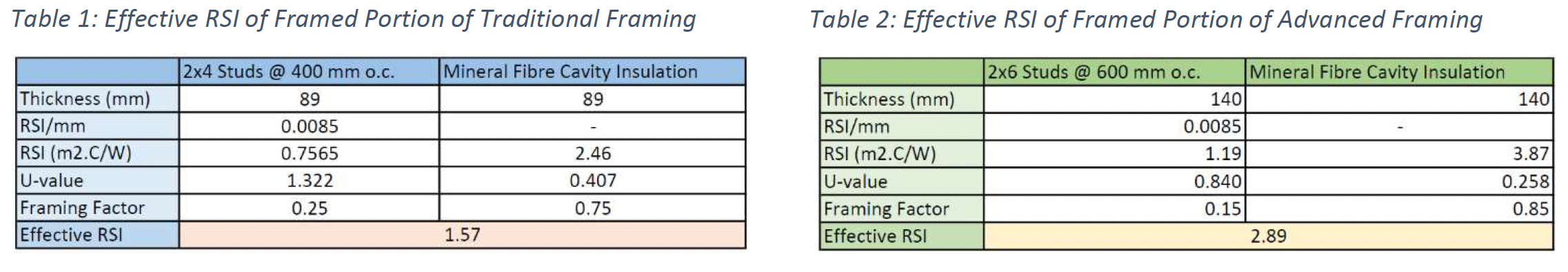

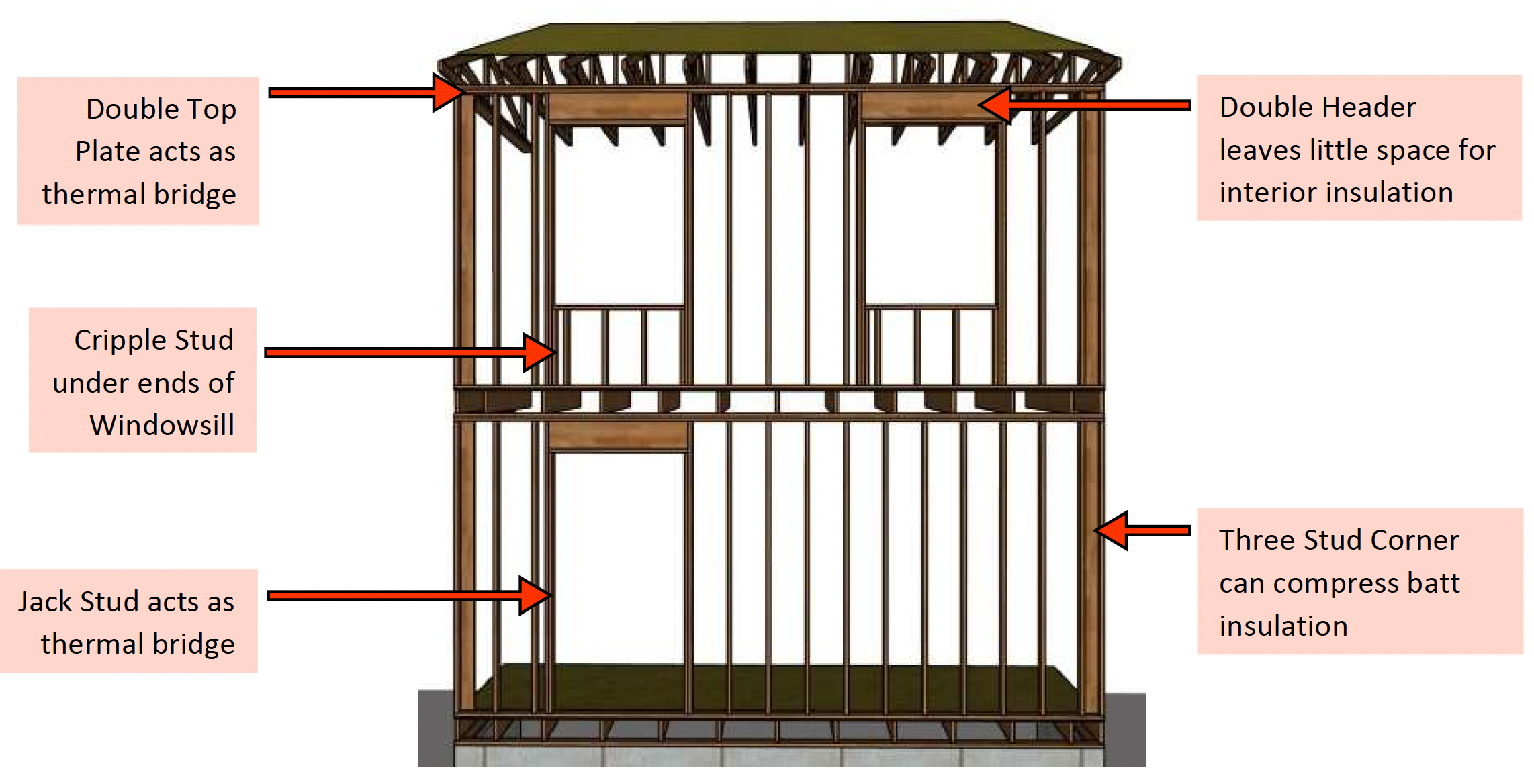

Table 1 and Table 2 below present the effective RSIs for the framed portion of our example Traditional and Advanced Framed wall systems respectively. Already we can see the Advanced Framing has an increased effective RSI of 84%.

Table 3 and Table 4 present the effective RSI of an entire assembly when including the thermal contributions made by the framed portions of the Traditional Framing and Advanced Framing.

The example Advanced Framing Assembly would resist 66% more conductive heat transfer than our example Traditional Framing Assembly. A lot of heat loss through the building envelope occurs via air leakage so coupling Advanced Framing techniques while emphasizing an airtight building envelope are an effective strategy to reducing overall home conditioning energy consumption.

Conclusion

Advanced Framing techniques reduce the number of potential thermal bridging locations for continuous insulation to thermally guard, while deepening and widening the stud cavities to accommodate more cavity insulation. These factors together make Advanced Framing well worth due consideration for any new building envelope project, and when faced with supply shortages and price hikes of wood products, the value of thoughtful framing design makes even more sense!

Works Cited

- 2021 Lumber Market Outlook. (2021, 02 22). Retrieved from Canadian Forest Industries

- Lstiburek, J. (2010). Advanced Framing. Building Science Corporation.

- Tables for Calculating Effective Thermal Resistance of Opaque Assemblies. (2016, 02 23). Retrieved from NRCan – Government of Canada

Appendix

Traditional Framing

Advanced Framing